RTP for methanol collection and transmission 17mm-12Mpa

$0.2≥500Others

| Payment Type: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Min. Order: | 500 meter |

| Port: | Qingdao Port |

$0.2≥500Others

| Payment Type: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Min. Order: | 500 meter |

| Port: | Qingdao Port |

Model No.: 603--17mm-12Mpa

Place Of Origin: Shaanxi, China

Brand Name: Yanchang NR Co.,Ltd

Material: PE-Al-PE, Polyethylene

Specification: 2.5Mpa,6.4Mpa,12Mpa,16Mpa,20Mpa,25Mpa

Nominal Inner Diameter: 17mm

Nominal Pressure Grade: 12Mpa

Average Inner Diameter: 17mm±0.5

Standard: SY/T6662.2-2020 Q/XXCJ282-2020,

Color: black

Minimum Wall Thickness: 5.5mm±0.5

Blasting Fusion: 36Mpa

Minimum Bend Radius: 300mm

Reference Weight: 0.5kg

Temperature Range: -40~40 ℃

Sample: Free

| Selling Units | : | meter |

| Package Type | : | Packed in blue polypropylene film |

Standard: SY / t6662 2-2020 Q/XXCJ282-2020

Appearance: Reinforced Thermosetting Resin Pipe is black smooth

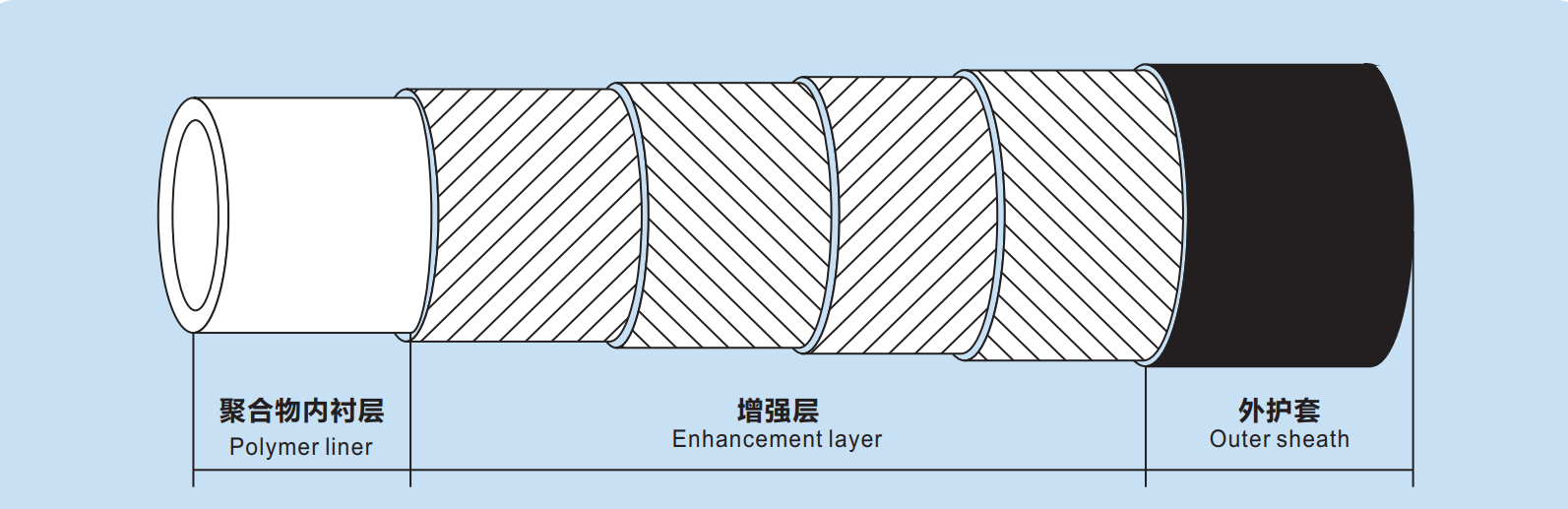

Structure: Flexible High Pressure Composite Pipe for methanol collection and transmission is composed of high molecular functional polyethylene resin, bonding resin, nylon, 1-4 layers of polyester industrial filament winding and impact resistant polyethylene resin.

Features of Reinforced Thermoset Resin Tubes RTR

| Product code | Nominal Inner diameter mm | Nominal pressure Grade MPa | Average Inner diameter mm | Minimum Wall thickness mm | Blasting Fusion MPa | Minimum Bend Radius mm | Reference Weight kg |

| 603-17-12 | 17 | 12 | 17±0.5 | 5.5±0.5 | 36 | 300 | 0.5 |

| 603-17-16 | 17 | 16 | 17±0.5 | 5.5±0.5 | 48 | 300 | 0.5 |

| 603-17-20 | l7 | 20 | 17±0.5 | 5.5±0.5 | 60 | 300 | 0.5 |

| 603-17-25 | 17 | 25 | 17±0.5 | 5.5±O.5 | 75 | 300 | 0.55 |

| 603-17-32 | 17 | 32 | 17±0.5 | 6±0.5 | 96 | 300 | 0.56 |

| 603-25-2.5 | 25 | 2.5 | 25±0.5 | 5.5±0.5 | 7.5 | 400 | 0.75 |

| 603-25-12 | 25 | 12 | 25±0.5 | 5.5±0.5 | 36 | 400 | 0.75 |

| 603-25-16 | 25 | 16 | 25±0.5 | 6±0.5 | 48 | 400 | 0.75 |

| 603-25-20 | 25 | 20 | 25±0.5 | 6±0.5 | 60 | 400 | 0.75 |

| 603-25-25 | 25 | 25 | 25±0.5 | 6.5±0.5 | 75 | 400 | 0.78 |

| 603-25-32 | 25 | 32 | 25±0.5 | 7.5±0.5 | 96 | 400 | 0.8 |

Shaanxi Yanchang Petroleum Northwest Rubber Co., Ltd. flexible composite tube division was established in March 2015. Flexible Compound Hose Division is a high-tech department dedicated to R&D/production/sales/after-sales service. A high-tech division dedicated to R&D/production/sales/after-sales service of flexible composite high-pressure oil transmission pipes. The business unit has 155 employees, including 8 technicians.

Received API Q1 Quality System Certificate and API 15s Product Certificate from American Petroleum Institute in January 2021; received Safety Mark Certificate for Mining Products.

In terms of production, it has eight domestic advanced production lines, mainly including eight domestic advanced production lines for water injection pipes, oil transmission pipes, gas transmission pipes, alcohol injection pipes, downhole composite pipes, and fiber-reinforced polyethylene pipes for coal mines.

Tel: 13619106316

Mobile Phone: +8615353135666

Email: 18629422510@163.comAddress: No. 1, Xihua Road, High tech Zone, 咸阳, 陕西 China

Website: https://www.cnrtp.com

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.